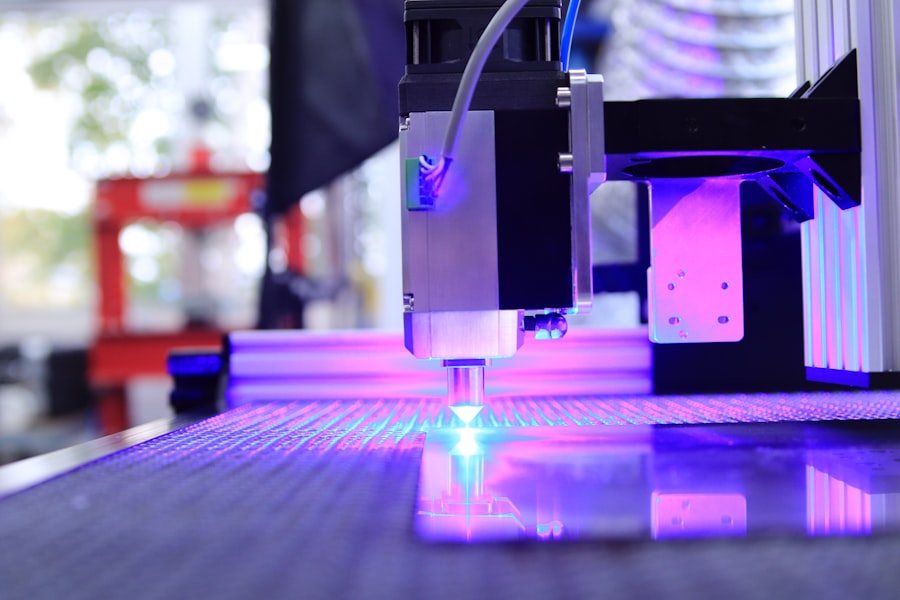

Allfs3d is a revolutionary 3D printing technology that is changing the face of the manufacturing industry. It offers a next-gen solution for creating three-dimensional objects with unprecedented speed, accuracy, and cost-effectiveness. This technology has the potential to transform various industries, from aerospace to medical, by providing a more efficient and sustainable manufacturing process.

Key Takeaways

- Allfs3d is a revolutionary 3D printing technology that is changing the face of manufacturing industry.

- Allfs3d works by using a unique process that allows for faster and more precise printing than traditional 3D printing methods.

- The benefits of Allfs3d include increased efficiency, reduced waste, and the ability to create complex designs with ease.

- Allfs3d has applications in a wide range of industries, from aerospace to medical, and is making 3D printing more accessible and affordable.

- While Allfs3d has many advantages over traditional 3D printing, there are still challenges and limitations to be addressed in the coming years.

Understanding the Working of Allfs3d: The Next-Gen 3D Printing Solution

Allfs3d works on a different principle than traditional 3D printing methods. Instead of using layers of material to build an object, it utilizes a unique additive manufacturing process that involves the deposition of a liquid resin that solidifies when exposed to specific wavelengths of light. This allows for faster and more precise printing, as the resin can be cured in a matter of seconds.

The materials used in Allfs3d are specially formulated resins that have specific properties to meet the requirements of different applications. These resins can be transparent, flexible, or rigid, depending on the desired outcome. They also have excellent mechanical properties, such as high strength and durability, making them suitable for a wide range of applications.

Benefits of Allfs3d: How It’s Changing the Face of Manufacturing Industry

One of the major advantages of Allfs3d over traditional manufacturing methods is its cost-effectiveness. Traditional manufacturing processes often involve expensive tooling and setup costs, which can be prohibitive for small businesses or individuals. With Allfs3d, there is no need for tooling or setup, as the objects are created directly from digital files. This significantly reduces the cost of production and makes it more accessible to a wider range of users.

Another benefit of Allfs3d is its time-saving capabilities. Traditional manufacturing methods can be time-consuming, with long lead times for tooling and production. Allfs3d eliminates the need for tooling and allows for rapid prototyping and production. This means that products can be brought to market faster, reducing time-to-market and increasing competitiveness.

Applications of Allfs3d: From Aerospace to Medical Industry

Allfs3d technology has found applications in various industries, including aerospace, automotive, medical, and consumer goods. In the aerospace industry, Allfs3d is used to create lightweight components with complex geometries, reducing weight and improving fuel efficiency. In the medical industry, Allfs3d is used for the production of custom implants, prosthetics, and surgical guides, allowing for personalized and precise solutions.

Specific examples of products and components that have been manufactured using Allfs3d include aircraft parts, dental models, jewelry, and consumer electronics. The ability to create complex geometries with high precision makes Allfs3d a versatile technology that can be applied to a wide range of applications.

Allfs3d vs Traditional 3D Printing: A Comparative Analysis

When comparing Allfs3d with traditional 3D printing methods, several factors come into play, including speed, accuracy, and cost. Allfs3d offers significant advantages in all these areas.

In terms of speed, Allfs3d is much faster than traditional 3D printing methods. The ability to cure the resin in seconds allows for rapid production of objects, reducing lead times and increasing productivity. Traditional 3D printing methods often involve slow layer-by-layer deposition of material, which can take hours or even days to complete.

In terms of accuracy, Allfs3d also outperforms traditional 3D printing methods. The ability to cure the resin with high precision allows for the creation of intricate details and complex geometries that are not possible with traditional methods. This makes Allfs3d ideal for applications that require high levels of precision and fine details.

In terms of cost, Allfs3d offers significant cost savings compared to traditional 3D printing methods. The elimination of tooling and setup costs reduces the overall cost of production, making it more affordable for small businesses and individuals. Additionally, the ability to produce objects quickly and efficiently reduces labor costs and increases productivity.

How Allfs3d is Making 3D Printing More Accessible and Affordable

One of the key advantages of Allfs3d is its ability to make 3D printing technology more accessible and affordable. Traditional 3D printing methods often require expensive equipment and materials, making it difficult for small businesses or individuals to adopt the technology. Allfs3d eliminates the need for expensive equipment and materials, making it more accessible to a wider range of users.

Additionally, Allfs3d offers a more cost-effective solution compared to traditional 3D printing methods. The elimination of tooling and setup costs reduces the overall cost of production, making it more affordable for small businesses or individuals. This opens up new opportunities for entrepreneurs and innovators to bring their ideas to life without breaking the bank.

Future of Allfs3d: Predictions and Possibilities

The future of Allfs3d looks promising, with potential developments and advancements on the horizon. As the technology continues to evolve, we can expect to see improvements in speed, accuracy, and material options. This will open up new possibilities for applications in various industries, from aerospace to healthcare.

One potential development is the integration of Allfs3d with other manufacturing processes, such as CNC machining or injection molding. This would allow for the creation of hybrid manufacturing processes that combine the benefits of Allfs3d with the strengths of other technologies. For example, complex geometries could be created using Allfs3d, while high-volume production could be achieved using injection molding.

Allfs3d and Sustainability: How It’s Contributing to a Greener Future

Allfs3d is not only revolutionizing the manufacturing industry but also contributing to a greener future. Traditional manufacturing methods often involve wasteful processes, such as subtractive manufacturing or casting, which generate a significant amount of waste material. Allfs3d, on the other hand, is an additive manufacturing process that only uses the material required to create the object, minimizing waste.

Additionally, Allfs3d allows for the creation of lightweight components with complex geometries, reducing weight and improving fuel efficiency. This has significant environmental benefits, as it reduces the carbon footprint of transportation and energy consumption.

Challenges and Limitations of Allfs3d: What to Expect in the Coming Years

While Allfs3d offers many advantages over traditional 3D printing methods, it also has its limitations and challenges. One of the main challenges is the limited range of materials available for Allfs3d printing. Currently, the resins used in Allfs3d are limited to specific properties and may not be suitable for all applications. However, ongoing research and development are expected to expand the range of materials available for Allfs3d printing in the coming years.

Another challenge is the scalability of Allfs3d technology. While Allfs3d is well-suited for small-scale production or prototyping, it may not be suitable for high-volume production due to its speed limitations. However, advancements in technology and process optimization are expected to address this limitation in the future.

How to Get Started with Allfs3d: A Beginner’s Guide to 3D Printing with Allfs3d

Getting started with Allfs3d is relatively straightforward, although it does require some initial investment in hardware and software. Here is a step-by-step guide on how to get started with Allfs3d technology:

1. Acquire an Allfs3d printer: There are several manufacturers that offer Allfs3d printers, so choose one that suits your needs and budget. Consider factors such as build volume, resolution, and compatibility with different materials.

2. Install the necessary software: Allfs3d printers require specific software to convert digital files into printable objects. Install the software provided by the printer manufacturer and familiarize yourself with its features and capabilities.

3. Prepare the digital file: Use computer-aided design (CAD) software to create or modify a digital file of the object you want to print. Ensure that the file is in a format compatible with the Allfs3d printer software.

4. Set up the printer: Follow the manufacturer’s instructions to set up the Allfs3d printer, including calibrating the build platform and loading the resin.

5. Import the digital file: Use the Allfs3d printer software to import the digital file and prepare it for printing. Adjust settings such as resolution, layer thickness, and support structures if necessary.

6. Start the printing process: Once everything is set up, start the printing process and monitor it closely. Ensure that the resin is properly cured and that there are no issues with adhesion or layer separation.

7. Post-processing: After the object is printed, remove it from the build platform and clean it according to the manufacturer’s instructions. Depending on the material used, additional post-processing steps such as curing or polishing may be required.

Tips and tricks for successful Allfs3d printing:

– Familiarize yourself with the capabilities and limitations of your Allfs3d printer.

– Experiment with different materials and settings to achieve optimal results.

– Ensure that your workspace is well-ventilated, as some resins may emit fumes during printing.

– Regularly clean and maintain your Allfs3d printer to ensure optimal performance.

– Stay updated with the latest advancements and developments in Allfs3d technology to make the most of your printing experience.

In conclusion, Allfs3d is a revolutionary 3D printing technology that is changing the face of the manufacturing industry. Its unique additive manufacturing process and specially formulated resins offer significant advantages over traditional 3D printing methods. Allfs3d is making 3D printing more accessible and affordable, with applications in various industries. While it has its limitations and challenges, ongoing research and development are expected to address these in the coming years. With its potential for future advancements and contributions to sustainability, Allfs3d is set to transform the manufacturing industry in the years to come.

If you’re a fan of allfs3d, you’ll definitely want to check out this fascinating article on the future of 3D printing technology. Discover how 3D printing is revolutionizing various industries and opening up new possibilities for innovation. From healthcare to manufacturing, this article from Changyouby.com explores the incredible potential of 3D printing and its impact on our world. Don’t miss out on this insightful read – click here to dive into the world of 3D printing! (source)

FAQs

What is allfs3d?

allfs3d is a software tool used for 3D printing. It is designed to convert 2D images into 3D models that can be printed using a 3D printer.

How does allfs3d work?

allfs3d uses a process called photogrammetry to create 3D models. It takes multiple 2D images of an object from different angles and uses algorithms to create a 3D model from those images.

What file formats does allfs3d support?

allfs3d supports a variety of file formats, including STL, OBJ, and PLY.

What are the system requirements for allfs3d?

allfs3d can run on Windows, Mac, and Linux operating systems. The software requires a minimum of 4GB of RAM and a graphics card with at least 1GB of memory.

Is allfs3d free?

No, allfs3d is not a free software tool. It is available for purchase on the official website.

What are the benefits of using allfs3d?

allfs3d allows users to create 3D models from 2D images quickly and easily. It is also a cost-effective solution for those who do not have access to expensive 3D scanning equipment.